Port Angeles CRTC: Giving New Flight to Aircraft Scrap

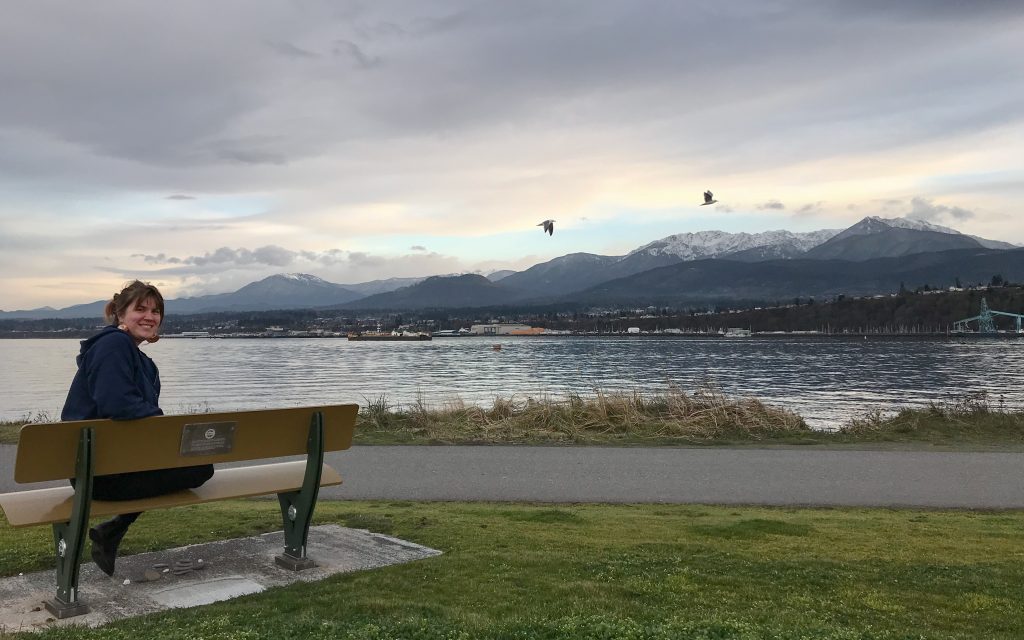

Before Nicole Wright started working at the Composites Recycling Technology Center, or CRTC, in Port Angeles, WA, two things pulled her to nearby Sequim: mountains and friendship. Having lived most of her life in Michigan, “being able to see any mountains, much less sometimes several mountain ranges at once, was just mind blowing.” As for friendship, one of her close friends, whom she met while studying abroad in Thailand, lives in Sequim. They’ve stayed close since returning to the United States, taking turns to visit each other. With a wistful smile, Nicole says, “as soon as I got home, I’d schedule another trip.” She scheduled one more trip for August of 2020. This trip, however, was one-way.

Moving to rural Washington presented one significant problem. With a B.S. in mechanical engineering from Michigan Technological University and experience in engineering and supervising at General Motors, the ads Nicole saw for work in lumber, shellfish processing, surrogacy, and food delivery didn’t look like great fits.

Then, Nicole found the CRTC, a 501(c)(3) not-for-profit in Port Angeles at the intersection of engineering and the environment. It was, well… perfect.

Except they weren’t hiring. Small technicalities such as that didn’t discourage Nicole. She met with the CEO, who said she could volunteer for the CRTC, which “could be a win-win for both of us.” By October, she was hired part time. And by January, she was full time.

The Composite Recycling Repurposing Technology Center

Founded in 2016, the Composite Recycling Technology Center is many things. However, Nicole emphasizes that “we’re not a recycling center, even though those two words are in our name.” Rather, she explains, “what recycling means, in terms of the CRTC, is repurposing material.” More specifically, the CRTC repurposes carbon fiber.

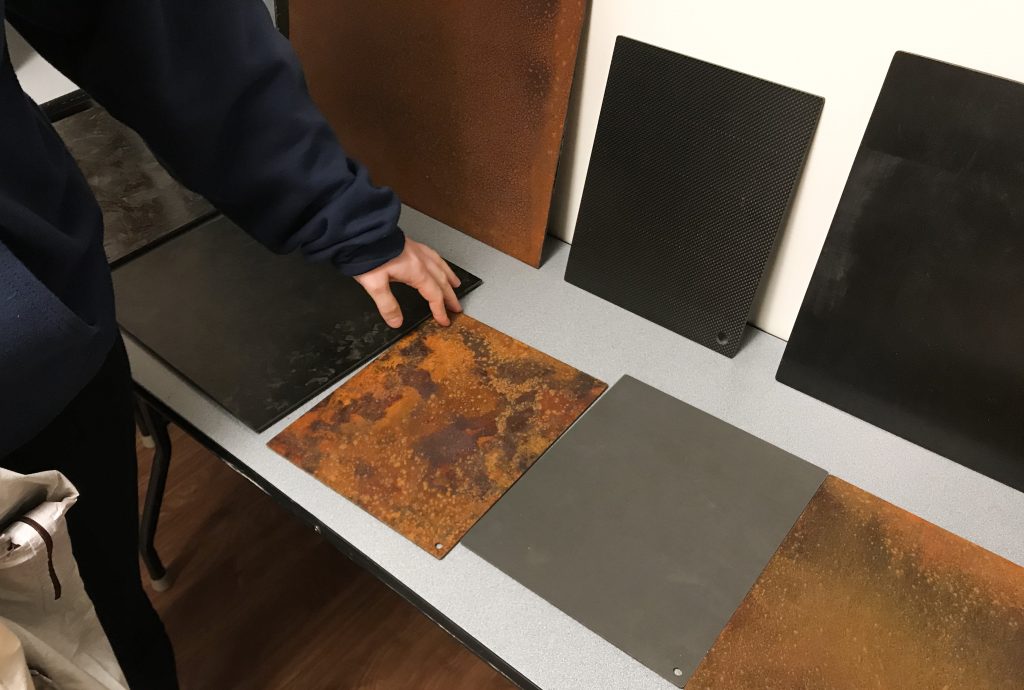

Most of the CRTC’s carbon fiber is scraps (expired, leftover, defected, or recalled material) from Boeing 777 and 787 airplanes. The CRTC is the first facility in the world to transform uncured (raw) carbon fiber composite scraps into new products. As such, they focus on not just manufacturing products, but on researching, developing, and training other organizations in the technology to manufacture products. This includes partnering with neighboring Peninsula College’s Advanced Manufacturing and Composite Technology program and lab (though this is currently on pause due to the pandemic).

Carbon Fiber: The Material Of Tomorrow

Carbon fiber is stronger, lighter, and easier to cut than steel. As a result, it has many potential uses. The CRTC’s first product was a pickleball paddle. Pickleball is big locally (Nicole doesn’t play herself, but that could change if she stays long enough), was invented in Washington State, and is the fastest growing sport in North America. Now, pickleball equipment is the linchpin of the CRTC. Nicole describes the net as their “hero product.”

The CRTC has a patent pending for a new material, Advanced CLT, which is a timber panel with carbon fiber strips that add stiffness and strength. The panels were chosen by Pennies for Quarters to use for a community of 24 energy-efficient tiny homes in Port Angeles for veterans without housing. The all-in-one nature of Advanced CLT allows each home to be built in less than three days.

“Not Just an Afterthought”

The carbon fiber was created to soar high above the earth, and much of it did that. But some of it is now pickleball equipment, benches, panels, medical devices, campers, and could soon be tiny homes. If it did not become these products, it would’ve been thrown in landfills. By instead repurposing the carbon fiber, the CRTC will save 1950 MWh of electricity and eliminate 2.5 million pounds of carbon dioxide emissions in one year. This is not merely a pleasant side effect—it is fundamental to the CRTC. As Nicole explains, “it defeats the purpose for us to buy brand new material… that is exciting to me.” Even more exciting, by researching, developing, and training people in the technology to repurpose carbon fiber, the CRTC’s environmental impact extends far beyond the carbon fiber that they themselves can repurpose.

The CRTC’s environmental sustainability is essential for Nicole. She explains: “I want to be working for an organization where environment is not just an afterthought. I want it to be an integral part of wherever I’m working.” For her, “it’s always cool when you can align your passions and your values with what you’re doing professionally.”

Pickleball Nets, Park Benches, and Tiny Homes Have Slightly Different Markets

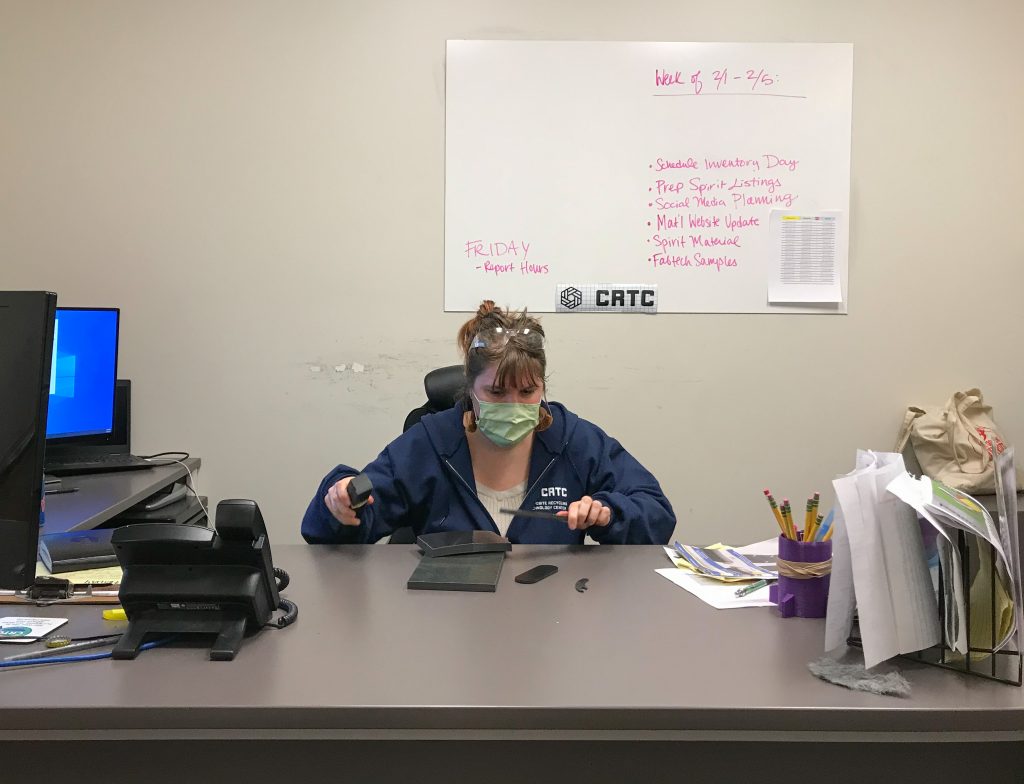

Nicole is the CRTC’s Sales Engineer and Social Media Manager. On a cloudy Monday in early March, she sits in her office. She wears safety goggle perched atop a stylishly messy bun, a light green face mask, tassel earrings engraved with the outline of Michigan (a Valentine’s Day present from her mom), and a navy CRTC sweatshirt. She explains to me that most of her time at work is spent managing donations, organizing materials for sale, finding and meeting with prospective customers, shipping material, and coordinating teams.

Working in sales at an organization with products as diverse as the CRTC’s comes with unique challenges. Nicole explains, “the person who’s buying the pickleball net is not the same person who’s going to buy a bench, who’s not the same person that’s building a tiny home and wants CarbonClad in it.” She has to market all the different products to all the different industries, which is difficult to do on a small team. Consequently, she says, they “have to be a lot more scrappy.”

However, being on a small, scrappy team has its fair share of advantages. As a result of the size, Nicole says “I have more of an influence. I wear more hats. My voice just matters more here.” For her, the autonomy is fresh air, something that’s in ample supply on the Olympic Peninsula. And for the rest of the world, the CRTC is only making the air fresher.