Major Home Repair: To Go Gas-Free, Perchance To Dream?

A global pandemic seems like as good a time as any for a major component of your house to collapse, right? Such was the case when the chimney on our 1895 Victorian fell down in a big windstorm in March. The entire thing. One fell swoop. Poof, clatter. Just fell the hell off. Nothing left. I was enjoying my morning coffee while talking on the phone with a dear friend in the automotive sector, trying to figure out what was going on in Fordlandia amid shutdowns and layoffs, when I felt the house shake. A great disturbance in the force.

A truck crashing into the house seemed unlikely, seeing as our house is separated from the street by a row of robinia pseudoacacia, a fire hydrant, a few cars, and a big fence. So, with an emergent horror, I realized that part of the house had fallen down. The casualties included the good trash can (RIP), the neighbor’s kitchen windows (ouch), part of a decaying block wall, and a Sterilite plastic tub. Bud, I said, I’ll call you back. I think our house is falling down.

Thus began a saga that involved 1) finding masons (kill me), 2) obtaining quotes, and, the purpose of this article, 3) considering what we might shoulda done differently.

As with everything else on this damn blog, let’s start with some history.

THE EVOLUTION OF THE CHIMNEY

The chimney, also known variously sometimes as chim-en-y (with three syllables) or, archaically, “chimbley,” is usually a masonry stack that extends up from the roof to a point, in most domestic code jurisdictions, two feet higher than any adjacent roof line within ten feet. Chimneys operate by a thing called science. Fire creates hot smoke, and this rises through the chimney, drawing in new air for combustion.

This ideal chimney design is what I would refer to as an architectural archaicism. We might call it a vestigial architectural artifact. It is a remnant of the days when heat was produced by relatively incomplete combustion of fuels, creating acrid smoke from things like coal or wood. This acrid smoke would build up carboniferous goop like creosote on the inside of the chimney, which posed a fire risk and also constricted airflow vital for both exhaust and combustion air supply. They used to recruit orphan boys to climb up on roofs and clean the inside of chimneys. This was before OSHA. The MSG of Dickens novels.

Modern technology flipped the script a bit. We moved from the inefficient coal furnii of yesteryear (yes, I know that’s not the appropriate plural) to slightly less but nonetheless still inefficient octopus, or “gravity-fed” furnii. These would then be replaced by what we think of as “modern” forced air systems in the latter half of the 20th century. Exhaust became cleaner as furnace efficiency increased. No more chimbley sweeps (sorry, Colin)! But exhaust temperatures also increased. The more you’re burning, the more (caloric, i.e. heat) energy you can extract from each unit of fuel. A “mid-efficiency” boiler’s exhaust is several hundred degrees.

But wait– now the script gets flipped again. Enter the high-efficiency furnace, also more precisely called the power-vented combustion appliance. The more energy you squeeze out of every unit of fuel, the cooler the exhaust becomes. At some point, the exhaust becomes too cool to rise up the chimney on its own. Enter the power vent, where a blower exhausts the lower-temperature exhaust, usually out the side of the house. You know when you walk through the neighborhood in the winter and you hear that gentle, “whzzzhhhh” sound coming from a little PVC pipe sticking out the side of the house? That’s a power-vented appliance. Furnaces are the most common, owing to their high fuel requirements in heating climates. But water heaters also have power-vented models (huge price premium, longer payoff, and therefore very uncommon in broke-ass Southeast Michigan). While exhaust from a mid-efficiency unit comprises 20% of the fuel heat– and is hot enough to cook dinner on (400-600°F)- exhaust from a 96% efficient furnace is more like warm breath (100-130°). This bump in efficiency is achieved using thermodynamic wizardry, like improved heat exchangers.

78% efficient– also known as AFUE for “annual fuel utilization efficiency”- has been the mandatory floor for efficiency since 1990. That was 30 years ago.

You see where I’m going? Our house was making a statement. The chimney collapse was the house telling us that the damn thing is irrelevant in 2020.

IS THE FUTURE ELECTRIC?

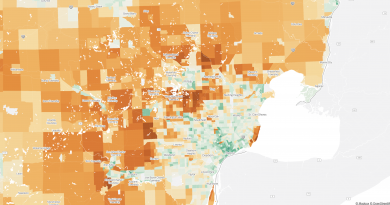

It’s a big thing in the green building movement right now to push for gas-free construction. In other words, instead of using gas heat, you’re using electric heat. ABC types– a.k.a. the right-wing corollary to the AFL-CIO- have pushed back on this. Oil and gas, they say, run through our veins, as freedom-loving Americans! More pragmatically, there’s also the fact that we aren’t entirely ready to get rid of fossil fuels as a society. The power grid is currently utterly unable to handle a completely electrified built environment.

A less valid complaint is that electric heat is “too expensive.” This presupposes the use of exclusively electrical resistance heating (which essentially creates heat by wasting electricity) rather than heating with a heat pump (which uses refrigeration).

It also ignores a fundamental tenet of green building, and that’s that you reduce energy load by building a better building envelope. More insulation. Better air sealing. The third floor of our house, for example, which is extensively insulated underneath the the floor (about R-20) and in the roof (a max of about R-25-30, given substantial spatial constraints– should be like twice that), doesn’t even need heat from the boiler. This isn’t just from the warmth underneath– even with the heat basically off in the rest of the house, it stays livable in the coldest winter. A big chunk of heating requirements comes from air losses (convective transfer), so, sealing the space solves a huge amount of your problem.

THE HEAT PUMP TRADEOFF

A heat pump operates on the same principles as an air conditioner. A “split system” heat pump, or usually a “mini-split,” heats and cools. It is so named because it extracts heat in the summer to blow cool air into the house, but can also– wait for it- extract heat from the cold winter air and blow warm air into the house. It’s air conditioning the cold. Yes, I know, it’s a weird idea. They’re magical, too.

You can even buy them delivered from Amazon, though we used Alpine Home Air, a Chicagoland company I was familiar with from my days there. The installation of the 12,000btu unit, which keeps the third floor cool during the summer, was largely painless for a skilled tradesman with some assistance. Although we did need to pay an HVAC tech $300 (for an hour of work) to pressure-test the lines before we could get it up and running.

What if we did this for the whole house? Since it’s summer, we wouldn’t have to do it immediately. This is good, because HVAC guys are always booked up. It’s a big house, though. Six rooms on the second floor, seven-ish rooms on the first floor (mostly open, simplifying air flow questions). Let’s do some napkin math to illustrate. Our boiler has an input of 187,500 btu/h. At a claimed efficiency of 78.5%, this means that it’s producing a maximum of 147,000btu/h in output (the rest is going up the chimbley). That could probably be done with something like three three-head mini-splits. At a cost of $4,000 each for that pictured one, though, we’re talking $12,000 in materials alone, plus a minimum of several thousand dollars for installation. We’d also need a house-wide insulation retrofit to reduce loads, both the more intensive summer cooling load and the higher delta-T in the winter. Even with the efficiency of a heat pump, jumping from, say, zero degrees to 70 degrees (F) is no small feat. We could do it inside of 30 grand, I’m sure. But 30 grand is way more than $3,000 plus the rest covered by insurance. (It’s doubtful to me that we could get any portion of an HVAC retrofit covered by that insurance claim).

I don’t know what the operating cost calculation looks like. It’s not too easy to convert between AFUE, HSPF, COP, SEER, and EER. The first is a fairly easy measurement of heat in, heat out, while the others involve other factors utilizing harder-to-quantify or harder-to-price calculations. Heat pumps, through some feat of thermodynamic sorcery, actually deliver more heat than the electricity that is used to generate it. This is because of the use of refrigerant, a magical substance. It is not quite, as an HVAC tech once told me, that “them things generate four watts of energy for every watt of energy you put in!” Rather, it’s that if you look purely at watts input versus BTU’s output, you end up coming up with something that, without the use of the Carnot cycle, or whatever, would be thermodynamically impossible. Suffice it to say, it’s not as easy as saying, “the electricity input creates more heat than it would if used in resistance heating, so it’s universally cheaper to operate the minisplits versus the boiler.” Electricity costs more per BTU than does natural gas.

On the other hand, it’s difficult to upgrade to a high-efficiency steam boiler. Steam is sort of out of vogue because it’s a little bit finicky compared to boilers, which utilize a somewhat more complicated, though somewhat more reliable, loop system with pumps. It’s also hard to find high-efficiency steam boilers.

THE CONSTRUCTION PROJECT

Back to the chimbley, though. Finding a mason was difficult. We made half a dozen inquiries and ended up only being able to actually get three bids. They were, in order, $8950, $6900, and $2900 (dubious). There was also a ballpark estimate from another builder that was in the $6000-some range. After promising they could start immediately, then delaying for six weeks and blowing off communication, the (quite well-reviewed, highly recommended) company we went with subcontracted to someone else. Even outside my contract law class, I knew that this was not only legal but fairly common. In this case, though, a lot of this work is referral-based, and therefore is relationship-based. So, it’s kind of bad etiquette to do it without at least mentioning it to the client.

Construction took a day for a team of able-bodied masons. Scaffolding was dropped off the night before in the back yard. Each of the centenarian-plus bricks– of which, miraculously, most survived the three story fall- were passed up by hand. The new masonry joints, wider than those of yore, meant they had to use fewer bricks, so we are using them in the garden.

The new chimney looks good.

Was it worth it?

In comparison to Going Electric? I mean, maybe. But we weren’t in a position to spend another five-figure sum of money in cash to go all-in on electric and do an envelope retrofit at the same time. In the mean time, though, maybe this good-looking piece of masonry will last for the next hundred years.

The Handbuilt City receives a tiny referral fee if you buy stuff from the lone link to Amazon. We do not have any relationships with any of the manufacturers or suppliers mentioned here.